andrew

Likes DAFs

Posts: 1,126

|

Post by andrew on Nov 2, 2017 20:01:54 GMT

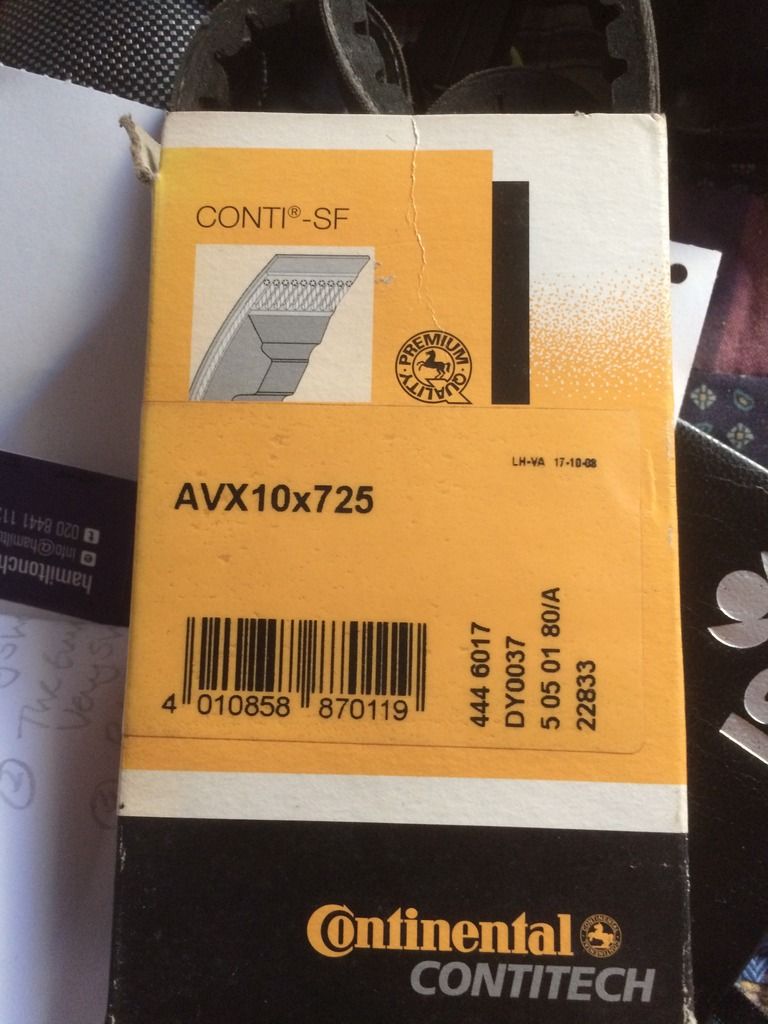

I was in my local motor factors this morning and (just as a joke!) I asked if they had a fan belt for a Daf 33. Boy, was I surprised when they said they had TWO! I bought them on the spot!  If anyone needs one in the future these are still in use for certain agricultural machines. Over the next few days I need to adjust the oil pressure extension pipe I've fitted to my car, with a view to fitting an oil pressure gauge at a later date. The pressure sender unit is screwed to the underside of the near-side panel between the near-side front crossmember and the front wing. In fitting the extension pipe to the oil pressure output I had to use a 45 degree lubrication pipe, to which the extension pipe is attached. I need to use a little PTFE tape, to bind the joint to prevent it seeping oil. While I've the front panel off the car I'm going to put a new fan belt on the car as well as a newly refurbished dynamo. I'm going to leave the original fan belt in place secured around the oil cooler so that, if the fan belt on the car breaks I don't have to fiddle the new belt around the impeller to fit it! |

|

|

|

Post by starider on Nov 10, 2017 10:48:31 GMT

Hi Andrew, Just noticed you said about "fiddling" the generator belt around the impeller, never done it that way,always find it easier to pop off the impeller guard and remove the impeller.this method avoids the risk of damaging the fins on the oil cooler.Trying to remember which belt from another vehicle is the same.Will post if I remember...........................starider

|

|

andrew

Likes DAFs

Posts: 1,126

|

Post by andrew on Nov 10, 2017 17:28:19 GMT

I spent an energetic day sorting this out! I removed the bumper, front grille, air intake and impeller before carefully passing the new fan belt through and over the oil cooler. Although there is enough room (just!) for 2 fan belts; one in use and one spare, secured against the oil cooler, I decided that it wasn't worth the risk of the fan catching in the pulley, so I removed the second belt. At least I've had experience of fitting and removing the fan belt on a 33 now, although I STILL wouldn't want to have to do this at the roadside!

As to the oil pressure gauge, although I have bought the gauge and the associated pipework, I'm having a problem with the joint on the engine block. Although the original Daf oil pressure warning lamp sender sealed perfectly, with no leaks at all, the 45 degree union I bought has weeped, no matter how much P.T.FE. tape I used on it! Never mind, I've put everything back as it should be and I'll have another think about this. What I've left in place is the pipe from the engine block to the near side and the oil pressure sender unit; it fits perfectly underneath the near side panel in front of the wheel arch and Daf even left an opening for the bolt to go in!

In other Daf-related news, I took the opportunity to re-route the fuel line while I had the grille off, as it had been passing over the top (and dangerously close to!) the off side exhaust manifold. I routed the rubber pipe from the metal feed pipe the tank, forwards along the strut and then doubled it back 180 degrees and took it behind the engine, behind the heater pipe and then under the dynamo to the fuel pump. I fitted a new in-line filter, too, which is under the horn.

|

|